- PRODUCT

- HOME

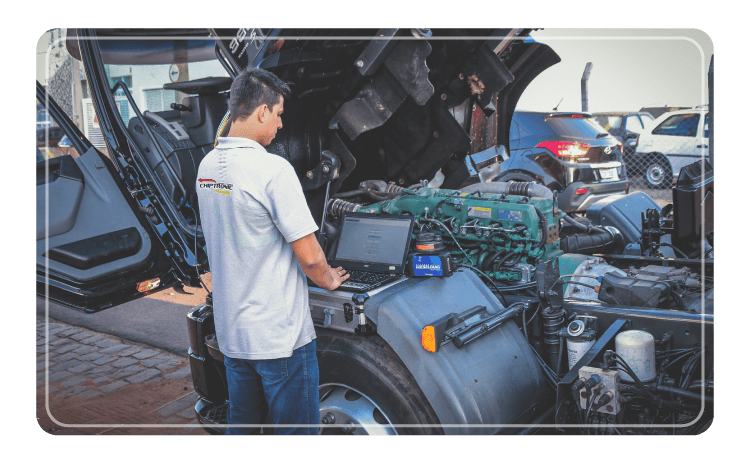

Become skilled in an automotive area still lacking in the market and learn diagnostic techniques in the best diesel electronic injection course in Brazil.

The course has instructors with extensive experience in automotive diagnostics and advanced measurement equipment , air-conditioned training room equipped with modern tools, in addition to ample space for practical training and application of contents.

Classes of 10 people and Chiptronic certification, a company that has been in the market for over 20 years, known worldwide for its technology innovations.

Content:

• Emphasis on practical diagnostics on a real diesel vehicle, providing the student with the knowledge to make diagnoses

on any diesel cycle vehicle.

• Applications and operation of sensor elements in the diesel cycle.

• Interpretation of electrical schematics during practical tests.

• Common Rail system operation analysis comprising the different injection cycles: pre-injection,

main injection and post injection.

• Presentation of Diesel aftertreatment systems.

• Practical vehicle tests available.

Prerequisites:

• Basic knowledge of diesel electrical and mechanical quantities.

Duration: 12 hours.

Programming:

Day 1: Principles of combustion and electronic injection applied in the Diesel cycle. Applications and operation of sensor elements in the diesel cycle. Practical tests and interpretation of signals in sensors studied in the classroom with the aid of multimeter. Analysis of different signals: rotation, phase and accelerator pedal with the aid of oscilloscope. Studies and practical tests on CAN (Controller Area Network) communication lines with the aid of multimeter and oscilloscope. Interpretation of electrical schematics during practical tests.

Day 2: Functional analysis and practical tests on injectors / fuel injection units. Voltage variations in different systems. Common Rail system operation analysis comprising the different injection cycles: pre-injection, main injection and post-injection. Analysis and testing of actuators such as pressure regulating solenoid valves and others. Presentation of peripheral sensors of the after treatment system. Presentation of diesel aftertreatment systems. Practical vehicle tests available.

» No manual was found

» No application table was found

» No download was found

» No video was found

Phone number list

| Cell Phone Number | Operator |

|---|---|

| 14 9 9629-8203 | Vivo |

| 14 9 9868-2468 | Vivo |

| 14 9 9627-9526 | Vivo |

| 14 9 9727-9923 | Vivo |

| 14 9 9769-5986 | Vivo |

| 14 9 9806-6426 | Vivo |

| 14 9 9806-6307 | Vivo |

| 14 9 9810-5789 | Vivo |

| 14 9 9702-3026 | Vivo |

| 14 9 8120-1678 | Tim |

| 14 9 8120-7806 | Tim |

| 14 9 9163-2269 | Tim |

| 14 9 9613-5156 | Claro |

| 14 9 8104-7079 | Claro |